Similarly to realizing where BASIC Engineering stops (see corresponding post) it’s interesting to realize that DETAIL Engineering does not produce all execution drawings: some are left to the construction contractor to develop.

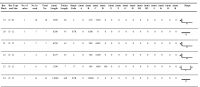

The civil DETAIL design performed by the EPC Contractor, e.g. that of a foundation or a concrete structure, entails design, calculations and issue of the re-inforcement and formwork drawings (as shown on page 77). The Bar Bending Schedule (see illustration) which is required for the prefabrication of the rebars, is produced by the civil contractor.

Building detailed design is not usually developed by the EPC Engineer, which merely defines its needs to the building construction contractor.

The EPC Engineering produces guide drawings, which will include:

The structural design, calculations and all structural drawings for the building and its foundation will be done to the civil contractor. So will the HVAC detailed design (equipment selection, flow diagram, ductwork routing), Fire & Gas and Telecom cable routing, design of the lighting and small power, plumbing networks, finishing schedules (doors etc.) etc.

The latter will particularly entail co-ordination all these trades, to avoid interferences.

The rationale for the EPC contractor to leave the building detail design to the construction contractor is that it has little cost impact and is time consuming. The EPC engineer’s always stretched resources concentrate on either critical or high cost items.

For On-shore Steel structures, such as pipe-racks etc, the EPC Engineer will perform the design, calculation and sizing of the members but no detail any further. Its work will stop at the issue of the Steel structure design drawings, such as the one shown on page 84. These are "on-line" drawings, indicating of the size of profiles, dimensions & elevations.

Connections between steel members, in particular, will not designed/sized by the EPC Engineer but left to the steel structure fabricator. The EPC contractor will simply provide the latter typical drawings, design criteria and individual loadings. The steel structure fabricator will perform the sizing of the connections and produce the corresponding calculations note and detailed drawings.

The fabricator will also produce all drawings used in fabrication (shop drawings) and erection. See samples shown on pages 85 and 86.

In Piping, the level of details to which the EPC Engineer goes is very high, with the issue of the Piping Isometric drawings. The latter are nevertheless not directly used for construction. Indeed, these are "Design" Isos, to which fabrication information (indication of welds following split in spools) must be added. Spooling, resulting in the issue of Shop Isos, is done by the piping construction contractor. Difference between Design and Shop isos are shown on page 114.

While leaving design work to the construction sub-contractors, the EPC Contractor must ascertain the latter’s design office resources and capability. Early follow-up of production of the latter (through put and quality) will allow early identification and mitigation of a bottleneck.