Contracts specify how a contractor’s entitlement to an extension of the project completion date due an event attributable to Company shall be determined:

The completion date is extended by the impact of the event, as demonstrated by the schedule logic, on the completion date.

There will therefore be an extension of the completion date only if the event affects the critical path of the schedule network, i.e., a chain of activities with no float.

The calculation of an extension of time is therefore totally dependent on the integrity of the schedule network.

Let’s focus on what comes into this integrity:

- firstly, the integrity of the initial schedule, submitted for the Owner’s review and, once approved, becoming the baseline,

- secondly, the integrity of each schedule up-dates

The object of the present post is to give insights into the second bullet point: schedule up-dates.

The contract requires the contractor to update the project schedule periodically (usually the contractually specified period is a 30 calendar days period) and evidence whether the project completion date or contractual milestones are met or delayed.

At the end of any period, the up-date of the schedule consists of entering:

(more details about how the scheduler actually proceeds are given at the bottom of this text)

Hence the up-date consists of both:

and

When updating the schedule (the 5 steps above), the scheduler uses and relies on a variety of information, including:

- reports of actual work done, such as documents issued, purchase order placed etc.

- minutes of meeting, allowing to identify hold-up’s and make sure they are reflected,

- trend register, allowing to identify hold-up’s, in particular from Client, and make sure they are reflected

Once the 5 above steps are done, the scheduler will re-schedule the Project, by making a forward pass, which will give the latest forecasted dates of future activities and the Project Completion Date (CD).

This forecast, in particular that of the CD, is an estimate that will change at the next schedule up-date. Actions do NOT need to be taken at each schedule up-date should the CD slip beyond the required one.

Indeed, the CD might revert to the original one at the next up-date should, for instance, the lead time of an equipment prove shorter than expected etc.

Should the CD remain consistently delayed over few schedule up-dates (says 3 successive periods), the Planner will then consider a 6th step in the schedule up-date: re-planning.

From a contractual and commercial perspective, the up-date of the level 3 schedule is highly critical as the level 3 is the only tool that fully identifies and supports the existence of a causal link between the event and its consequence that is: a delay of activities of the critical path.

Only with such support Contractor can firmly establish its entitlement to an Extension Of Time (EOT) and identify the liable party.

If a CPY event impacts the critical path, this exercise will permit to quantify the extent of this EOT and, as a consequence, the cost that contractor may claim (time related costs).

The critical paths will become more precisely defined, and will change during the project execution.

As impact to the critical path forms the basis for the calculation of an EOT, it is essential that schedule up-dates properly reflect the current and critical paths(s).

This means that the level 3 schedule must be based on the up-to-date execution plan of the CTR, in order to allow assessing the true impact of any event.

Additionally, it is essential that all delays of CPY origin are reflected in the schedule up-date as the CTR’s obligation under the contract is to up-date the level 3 on a regular basis with all impacts.

Overlooking one delay event would forfeit CTR’s right to an EOT.

Annex:

DETAILS OF LEVEL 3 SCHEDULE UP-DATING OPERATION BY THE PLANNER:

STEP 1: REFLECT PROGRESS OF WORK DONE IN THE PERIOD

0) Do nothing for finished activities.

1) Activity that was already started in the previous schedule up-date and that was forecasted to finish in the reported period:

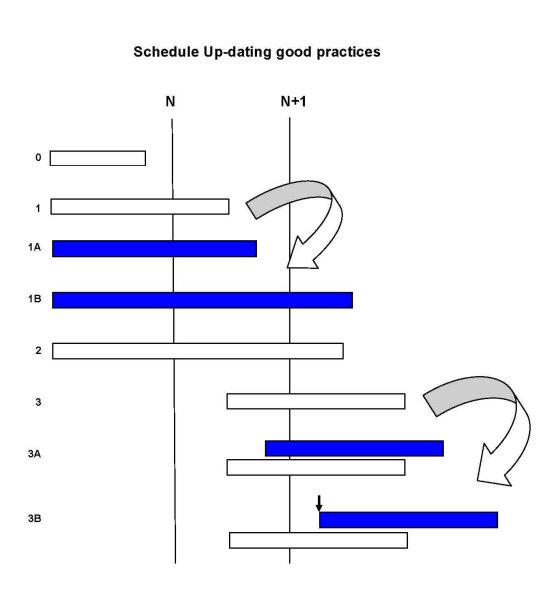

Let’s consider the two methods:

Say an activity has an original duration of 20 days and started 10 days ago. Say the progress is 50% at the cut-off. When asked, the concerned discipline states that the activity will only be completed in 20 days. Using the first method allows to set the finished date as per the estimate of the discipline by entering a remaining duration of 20 days. Thus from an initial duration of 20 days, the updated duration shall be 30 days.

Using the first method and entering the 50% percent progress figure would have the scheduling software calculate a remaining duration of 10 days (as 50% progress in 10 days leads to 100% of the activity to be completed in 20 days).

One sees that, due to the non linear progress of most activities, in particular Engineering activities, the first method is more suitable than the second.

2) Activity that was already started in the last schedule up-date and that was NOT forecast to finish in the reported period:

The planner might change the remaining duration, if required, upon advice from discipline about estimated remaining duration.

3) Activity that was forecasted to start in the reported period:

Note: do not extend the lag with the predecessor as this is not logical: the reason for the delay is not a lag between the 2 activities.

4) Activity that was neither forecast to start nor to finish in the reported period:

As this activity is linked to predecessors, it might shift automatically through the schedule logic as a result of the shift of its successor(s) due to start or finish in the reported periods and up-dated in steps 1 and 2.

Additionally, the planner might change the remaining duration, if required. This will happen, for instance, if the amount of work anticipated for the activity has a result of the project progressing, better definition etc

STEP 2: CORRECT THE NETWORK WITH LATEST AVAILABLE INFORMATION ABOUT THE PROJECT

Refine the schedule logic and task duration with the more precise information now available, e.g. equipment lead time, amount of work for activities etc.

This will also entail addition and deletion of activities. A schedule density indeed increases when time is closing in: its density will be high for the next three month, medium between 3 and 6 months and low beyond 6 months.

For instance, as soon as more information among a category of equipment will be known, one of them will need to be singled out as a long lead time, or requiring more time for assembly etc. E, P and C activities for this equipment will be separated form that of its equipment group by creating new activities.

Re-schedule and look at the impact on the CD.

Looking at the critical paths, correct some obvious mistakes to avoid unrealistic impact on the CD.

Do not go beyond this type of corrections. In particular, do not change the sequence or activity duration unless to reflect the true anticipated execution and latest information.

This gives the trend or forecast, reflecting the true estimated completion date on the basis of the actual progress and latest information to date.

Up to this point what the scheduler did is to reflect the true status of the project and to derive the trend, i.e. forecast completion date, nothing more.

This is similar to what the cost engineer would do while identifying the “to go”, i.e. what remains to be spent.

STEP 3 (NOT SYSTEMATIC): RE-PLAN, IF REQUIRED, TO REVERT TO THE ORIGINAL CD

This step, which takes time and requires reset of commitments from various parties, does not need to take place at each schedule up-date every month.

Additionally, from one month to the other, it may very well be that the anticipated delay to the CD will be resolved.

When review and re-planning is required to revert to the original CD, the following shall be done:

Review the different Critical Paths: